The 5G standard is truly a game-changer; its speed, latency and connection densities are such significant improvements over 4G that entirely new applications that simply weren’t previously viable now become possible. Remote surgery and driverless cars are good examples; both depend critically on the instant, no-latency response that only 5G can provide.

Emerging opportunities like these owe much to IoT growth as well as 5G’s promise. The IoT includes high volumes of geographically-distributed devices that will benefit hugely from 5G-enabled communications capability.

But 5G’s characteristics have major implications for hosting data centres, in terms of performance, capacity, and geographical distribution. Below, Alex Emms, Operations Director at KOHLER Uninterruptible Power (KUP), looks at the challenges, and how modern, modular UPS technology can contribute to solving them.

Expected 5G impact on data centres

The relationship between 5G and the IoT is highlighted by a Gartner survey[i], in which 57% of respondents reported that their main interest in 5G was to drive IoT communications – and with potentially billions of IoT-connected devices, the amount of data generated will be huge. 5G is estimated to be able to handle 1000 times more connected devices per metre than 4G without being affected by bandwidth congestion, meaning more devices can work in closer proximity.

Additionally, 5G’s bandwidth and speed – estimated to be between 20 and 100 times faster than 4G – will allow it to compete with ISPs’ traditional broadband wired connections; so creating a further huge demand for data processing and storage capacity, and hence data centres. Data centres will also need to compress data to handle the increase in, for example, video streams. This will require new technologies and compression algorithms.

Data centres and telecom providers will therefore require the right high-performance hardware and technology to handle the routing and switching necessary to match the flow of data; additionally, they will need to manage their power consumption. This is not only for cost-efficiency, but also due to increasing pressure to demonstrate a greener footprint, and in many cases, the need to avoid upgrading power feeds into the data centre. One solution is installing software defined power (SDP) based on both hardware and software that can skilfully allocate power throughout the data centre, and another is to select more energy-efficient equipment, to save both direct energy and cooling costs.

4G-enabled data centres will have the capacity for handling 5G data. However, they will have to change their infrastructure to cater for 5G’s super-high (30 GHz to 300 GHz) frequencies. These frequencies will only work if devices are in close proximity to antennas. Therefore, we will likely see multiple input and output antennas (MIMOs) and many more small cells installed around public infrastructure.

Small cells have a clear advantage over traditional cell sites as they can be located in areas lacking space for large cell towers. What’s more, they are cheaper to deploy. Data centres will, however, need to be close enough to these cells to maintain 5G’s low latency performance and meet service-level agreements. Sometimes, micro data centres might even be deployed at cell tower bases, allowing limited data processing with even faster response times for critical applications like autonomous vehicles.

These trends will likely lead to the break-up of larger data centres into smaller, more local facilities close to these cells. New, low-latency IoT-type applications like the remote surgery and driverless cars examples will clearly depend on data processing, communications channels and power infrastructures that offer very highly reliability alongside ground-breaking performance. This will call for Tier 3 and Tier 4 data centres with near 100% redundancy.

Implications for UPSs

The above predictions for 5G indicate a proliferation of small and very small data centres – but these data centres, however small, must be just as reliable as the best of their larger counterparts. So how can UPS technology facilitate the scaled-down yet highly-reliable power solutions essential to such environments?

The answer lies with today’s transformerless modular topology, as exemplified by KOHLER Uninterruptible Power’s KOHLER PW 8000DPA UPS – See Fig.1. Designed for low to medium-scale high power density applications, the UPS offers high energy efficiency, 99.9999% (‘Six Nines’) availability and flexible scalability in tower or rack-mountable configurations.

While a single module can be used to deliver 10 kW or 20 kW, further modules can be added incrementally to increase capacity or provide N+1 (or N+n) redundancy. Up to 80 kW (60 kW N+1) rack-mounting capacity can be provided, with an ultimate capacity of 400 kW for two fully-populated tower versions in parallel.

The KOHLER PW 8000DPA’s rack-mounting capability and high power density allows it into restricted spaces, while its high energy efficiency minimises the heat to be extracted from such spaces. As well as the completely self-contained UPS, each module includes battery and communications capability. This allows monitoring of UPSs in remote data centres from a centralised location.

The system’s Decentralised Parallel Architecture (DPA) means that single points of failure are eliminated, and uptime is maximised. Mean time to repair (MTTR) is minimised, as the ‘hot swappable’ modules can be safely removed and replaced without interrupting power to the critical load.

Fig.1: KOHLER PW 8000DPA UPS system – rack-mounting version

Effective maintenance is essential too

While providing a UPS of suitable size, scalability, efficiency and availability is essential for the new-generation small 5G-oriented data centres, this alone is not enough. To be kept in prime condition and optimally reliable, the UPS, especially its battery, must be regularly monitored and maintained. This can be challenging for an implementation comprising many small data centres distributed over a wide geographical area.

An experienced and well-resourced UPS supplier like KOHLER Uninterruptible Power can solve situations like this. Firstly, they offer remote monitoring services including PowerREPORTER Remote UPS Monitoring, and PowerNSURE Battery Monitoring.

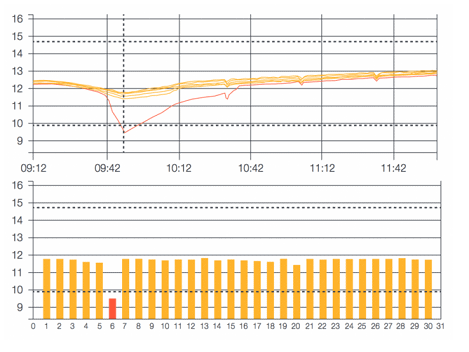

PowerNSURE not only provides battery monitoring, but also performs proactive maintenance. It checks every battery’s internal resistance, temperature and voltage, and reports on the results – see Fig.2. Additionally, it executes an equalisation process to keep battery charging voltages within operating range. By preventing gassing, dry-out and thermal runaway, this assures continuous battery availability.

PowerREPORTER communicates constantly with UPS systems, and detects any fault conditions or alarm messages. While customers can monitor all of their UPS systems centrally, any incident is reported to KUP’s Service Centre by email, complete with status and any available details. The Centre’s personnel can pass this information to the field team, allowing them to reach the UPS site within the contracted service agreement time, already briefed on the issue and equipped to resolve it rapidly.

Fig.2: PowerNSURE battery monitoring report, highlighting a weakness in Battery 6

KUP’s remote monitoring services are complemented by their nationwide team of trained field engineers. Covering the entire UK, this team not only responds to alarm callouts as described, but also performs scheduled maintenance visits to comply with any established service agreement. Emerging problems are fixed before they can cause failures, so the power protection system’s maximum possible availability is assured.

Conclusion

In recent years, popular news has focused on the drive by organisations like Google and Facebook to build hyperscale data centres. However, the rise of the IoT and expected growth in 5G means that, for many users, the emphasis will shift towards smaller, sometimes micro-scale facilities.

These will call for UPSs that are suitably scaled down, while still offering levels of availability associated with Tier 3 and 4 installations. They must be compact, scalable, simply installed, efficient, and easy to manage remotely.

But it’s not just about providing the right hardware. Critically, the UPS supplier must have the remote monitoring technology and field service infrastructure needed to guarantee that UPSs in multiple facilities spread over a wide geographical area unfailingly achieve their full performance and availability potential.

Reference