UPS systems, whether they are desktop units for single workstations, or installations for large data centres, need communications capability. This is primarily to raise alarms during mains power failures, and to provide other status information. However, communications channels also allow remote systems to control UPSs and optimise their configuration for prevailing load conditions.

UPSs exist to deliver uninterrupted, clean power throughout a utility mains disturbance or failure – but to avoid a system crash if the disturbance time exceeds the UPS’s battery autonomy, the UPS must communicate its operating status and activity to its critical load, and a generator if installed.

With communications, the UPS can signal a generator to start up and stabilise safely within the battery’s autonomy time. If no generator is available, the UPS can at least warn the critical load in time for it to perform a safe, organised, and possibly unsupervised shutdown while battery power remains available.

From volt-free contacts to wide area networks

Various modes of communication are available to fulfil this essential function, and others besides. These range from simple volt-free contacts, through point-to-point serial communications, to full networking. The best choice for an installation depends on its size and complexity.

The volt-free contacts can be used within a dry-port interface to communicate the UPS status to a remote monitoring station or local Building Management System (BMS), where it can be integrated with other building monitoring assets. Equally, external control signals – such as a ‘remote shut-down’ command – can be sent to the UPS as part of a site-wide emergency stop application.

In a small, simple system comprising a desktop UPS supporting a single workstation, a serial communications link, typically using RS-232 protocol, can be used to perform a controlled shut down of the workstation following a mains failure. In very basic systems, the link will be supported by vendor-supplied software running on the workstation. This typically includes a simple on-screen display of UPS parameters such as input voltage, current and battery state.

A larger UPS system supporting a data centre will more likely be connected as a network device on a Local Area Network (LAN) or Wide Area Network (WAN). Accordingly, it can communicate with a management centre that provides system monitoring and control of the entire UPS system and other network devices.

The communications link can be bi-directional. While the UPS can provide the network with a ‘server shutdown’ command at the appropriate time following a mains failure, the network manager may also be able to control the UPS from the management centre. This facility could be used, for example, to initiate a UPS battery test remotely.

A parallel UPS system also requires an inter-module communication facility that allows all the modules to communicate with each other to exchange parallel-control information, such as load sharing data. This is normally implemented by an inter-module, multi-drop serial communications link.

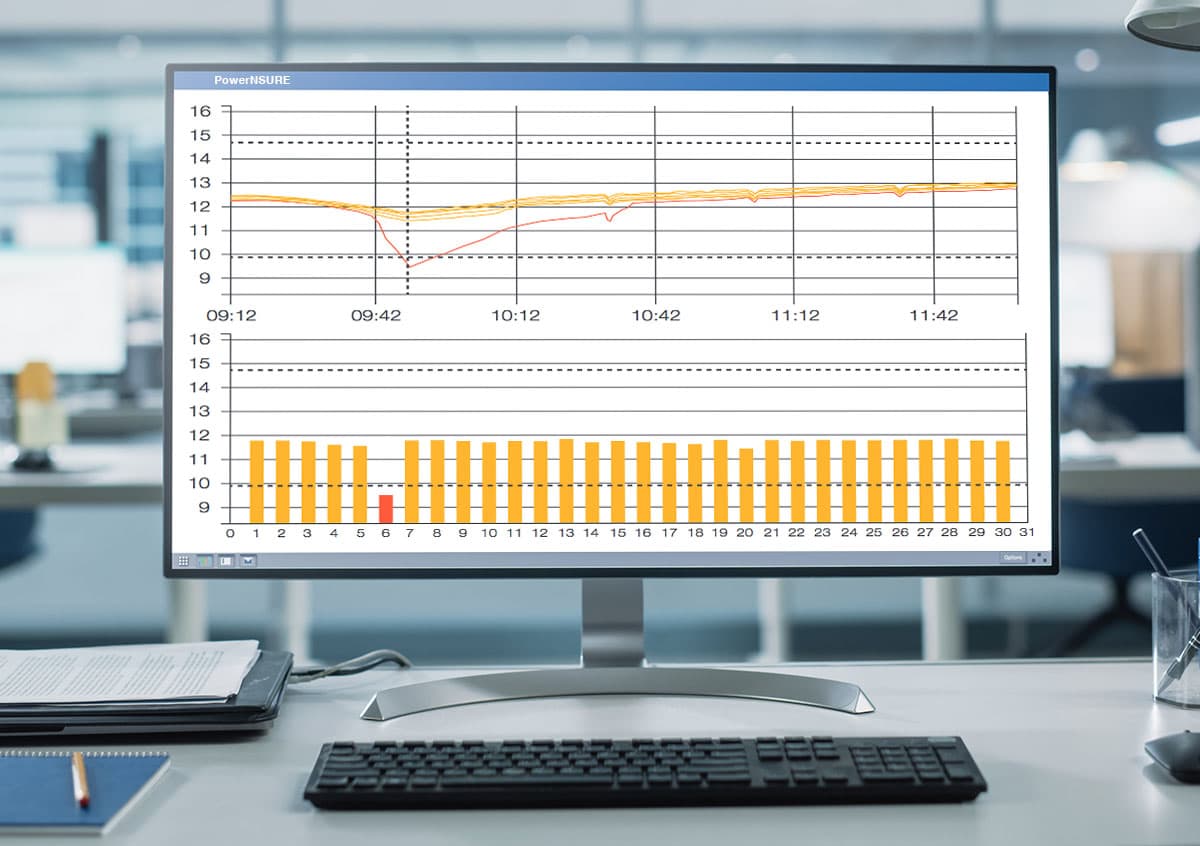

Remote management software

In addition to providing local or network-wide monitoring, a modern UPS installation may also include a facility to report UPS fault or status events to remote monitoring points using automated email or SMS messaging.

Remote management software, such as PowerREPORTER® from KOHLER Uninterruptible Power, can be programmed to initiate a dedicated customer response when a critical alarm event is received.

For example, it can immediately contact the client’s representative or the manufacturer’s service technician, who can then connect to the UPS Management Centre using a laptop to gain detailed information regarding the alarm. If necessary, the technician can then respond to the fault quickly and fully prepared.