Progress in UPS efficiency

Data centre operators are under continuous pressure to improve UPS and other equipment efficiency. Several factors are driving this need; concerns about excessive energy usage relate not only to controlling costs, but also to complying with stringent government regulation on curbing carbon emissions. Increasingly, organisations must demonstrate an effective green policy to satisfy their shareholders, customers and employees. Additionally, data centre installation size has been increasing, with hyperscale facilities that regard 400 – 500kVA UPS systems as basic building blocks. Increased scale magnifies any energy efficiency shortcomings.

Fortunately, UPS efficiency has improved over the years. According to KUP findings, it has progressed from 94% 10 years ago to 96% today, with 97% being forecast. This has been achieved through several technology advances. The first relates to the change from transformer-based to transformerless technology. Early UPS designs depended on a transformer to step up the inverter output voltage to a level compatible with the utility or generator supply. However, advances in power semiconductor technology and the appearance of the Insulated Gate Bipolar Transistor (IGBT) device have eliminated the need for a step-up transformer; this allows more efficient, smaller and lighter UPS designs.

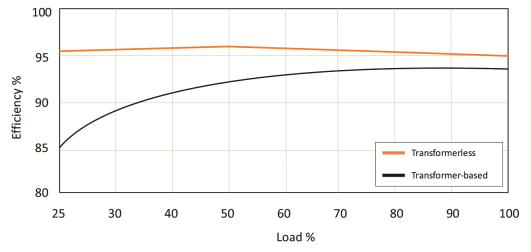

Overall, efficiency is improved by about 5%. The transformerless designs efficiency curve is flat, and above 95%, all the way from 25% loading to full loading. Transformer-based system efficiency is lower at full load, and drops away further as loading reduces to 25%. Transformerless energy savings are amplified because greater efficiency reduces heat losses and saves on the energy required for cooling.

Additionally, transformer-based designs use a phase-controlled input rectifier to provide a regulated DC voltage for battery charging and supplying the inverter. This presents a lagging power factor to the incoming supply, which falls further away from unity as the UPS load decreases. By contrast, transformerless designs inherently produce an input power much closer to unity and independent of the UPS load. This reduces input current magnitude and cabling and switchgear sizing, possibly reducing electricity costs.

If UPS loading drops below 25%, energy efficiency can be sharply reduced. However, a smart solution known as Xtra VFI is now available to address this. A modular double-conversion UPS with this mode enabled automatically adjusts the number of modules on line to match prevailing load requirements. Modules that are not needed are switched to standby but remain primed to start up and transfer to active mode if the load increases. The technique operates over the entire UPS load spectrum, but is especially valuable at loading below 25%, where UPS’s are least efficient.

In addition, Xtra VFI rotates the modules between active and standby, therefore extending the service life of the UPS. When the system calculates the optimal percentage value for maximum efficiency, it allows for desired levels of redundancy. This redundancy level, along with highest expected load step, can be configured by the user. In the event of a mains failure or alarm, Xtra VFI is deactivated automatically, while all modules are switched to Active mode.

Another approach, albeit one with pros as well as cons, is to operate the UPS in ‘Eco-mode’, where under normal operating conditions raw mains power is fed directly to the critical load. The UPS only switches the load to inverter output if it detects a mains aberration or interruption. This improves efficiency by cutting out the rectifier and inverter conversion stages, but exposes the critical load to the risk of power loss or damage. Accordingly, eco-mode is only used where the load is not critically sensitive to mains problems and/or where there is very high confidence in the mains supply quality.