Welcome to a series of articles on preventative maintenance and the benefits it can bring to your critical power protection devices; uninterruptible power supplies, emergency lighting and battery solutions.

Over 4 articles we will discuss capacitors, batteries, remote monitoring, fans and third-party maintenance. KOHLER Uninterruptible Power pride themselves on service excellence, making maintenance and response for your critical power system a priority. With a +90% first time fix rate and best-in-class customer NPS rating you can rest easy knowing you are in the best hands.

The components within KUP power protection devices are of a high quality to help ensure many years of trouble-free operation. In this first article we look at capacitors, what are they, how they work and how to ensure they continue to work to deliver smooth, continuous power.

What is a capacitor and how it works?

Several different applications of capacitors work together to ensure the critical load receives a supply of power that is stable both in voltage and frequency, no matter whether it is being fed by mains or battery power.

AC capacitors on a UPS input circuit provide input harmonic filtering and power factor control to improve electrical characteristics in the power system, lowering system costs, enhancing reliability and increasing the system’s life cycle.

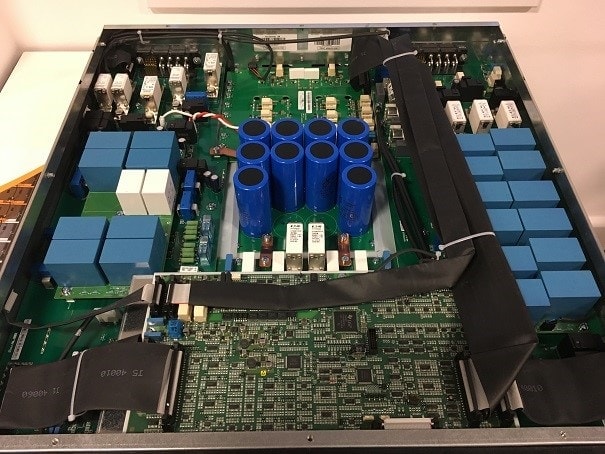

A typical UPS of the mid power range uses an average of ten power capacitors per system for filtering.

What are the different types of capacitors?

AC capacitors on a UPS output circuit provide voltage control and filtering of inverter waveform switching frequency and harmonic distortion, supplying reactive power to non-linear loads – this basically improves UPS output voltage.

DC capacitors provide an essential link between the input (rectification circuit) and the output (inverter circuit) of the UPS. The DC link capacitor is used to reduce the ripples in the rectified DC supply to the inverter and are essential part of the booster circuit.

Failure of capacitor

As with all models and manufacturers of UPS, AC and DC capacitors have a finite working life and should be replaced as part of an ongoing preventative maintenance regime. Their manufacturer recommends that capacitors should be replaced before they reach 5 years of operation on the assumption that the KOHLER PW UPS has been operated in ambient temperatures of less than 25ºC. If the capacitors should fail, they may cause damage to other components within the UPS system, which may result in great expense to repair and unforeseen downtime. The mode of failure for over-aged capacitors is such that this may also trigger fire alarm and suppression systems, further emphasising the need to replace them in line with manufacturer’s recommendations.

There are many reasons why capacitors fail, but these failures can often be picked up by a trained engineer during a preventative maintenance visit.

Here are some examples of symptoms of failure:

- Deformation

- Rise in temperature

- Burnt wires

- Leaking substance

Other types of failure include a “short” failure where there is a risk of the dielectric medium leaking and that , the capacitor may “burst”. The capacitors can also just stop working, which can be hard to detect as there is little physical evidence of a malfunction.

Consequences

The DC capacitors are located electrically between the rectifier and the inverter stage of the UPS. Should the DC capacitors fail, the rectifier may fail which can affect other internal components, dramatically increasing the repair costs and potentially putting the critical load at risk.

The AC capacitors are located in the input and output stages of the UPS. They act as a filter, and should they fail, smoke is likely to be issued – potentially triggering fire protection systems – and the UPS would switch to internal bypass. This means that the critical load would be supplied by raw mains and will not be protected from mains disturbance. Another possibility is that other internal UPS components could be affected, putting the critical load at risk.

Benefits of preventative maintenance when it comes to capacitors

- Ensure continuous uptime and availability of your UPS system

- Extend the lifetime of your system

- Avoid the risk of additional costs for repair

- Ability to allocate budget for component replacement

Importance should be given to the pro-active replacement of both AC and DC capacitors in a UPS system to ensure ongoing reliability and resilience of the system and in turn mitigate the risks to the critical load supported by it.

With a capacitor replacement programme from KOHLER Uninterruptible Power, new capacitors will be supplied with a 12-month manufacturer’s warranty and the old capacitors will be removed and disposed of safely.

If you have any questions about the health of your power protection system please get in touch with our Service Department: [email protected] or call 01256 386752