The term Internet of Things, or IoT, may sound as broad-brush as you can imagine but in reality it accurately encapsulates the breadth of devices which are or soon will be connected to the Internet. What’s more, it is an area set to witness sustained growth in the coming years. With this rapid increase in the number of connected devices, there will, understandably, be a corresponding rise in demand for real time data processing. As vital components of the data centre infrastructure, UPSs must offer sufficient scalability, flexibility and online availability to meet this expected demand – and must do so while complying with data centre real estate and budget constraints.

In this article, Kenny Green, Technical Support Manager at KOHLER Uninterruptible Power Ltd, a KOHLER company, looks at how operators can use today’s modular UPS technology to manage the implications of the Internet of Things.

The Internet of Things (IoT) is about adding a spark of intelligence, communications capability and an IP address to everyday objects in our home, office, factory or leisure environments – or in the transportation we use to move between them. On a personal scale, examples include fridges that become data sensors, reporting on the stock levels and freshness of their contents, sprinklers activated by moisture sensors or factory equipment that reports on its own health and need for preventative maintenance.

For the big picture, the IEEE is forecasting “Smart homes and workplaces, self-healing power grids, digital factories, cleaner transportation and immersive entertainment” as just a few examples of the IoT’s potential. The organisation is preparing a new ‘IEEE Standard for an Architectural Framework for the IoT’, intended to act as a catalyst for continued IoT growth, advancement and associated development of economic opportunities.

This growth is expected to be dramatic, with Gartner forecasting 26 billion devices installed by 2020. These deployment levels will generate large quantities of data that must be processed in real time. This will impact on data centre workloads, creating new security, capacity and analytics challenges. The enormous number of devices, coupled with the sheer volume, velocity and structure of IoT data, means that datacentre managers will need more forward-looking capacity management to proactively meet the business priorities associated with the IoT.

Impact on data centres

A key challenge to data centre operators arises from the IoT’s innately distributed nature. Connecting large volumes of such distributed data back to a single data centre site will not be technically or economically viable. Instead, organisations seeking to integrate an IoT structure will have to aggregate raw data in multiple, distributed mini data centres for initial processing. The resulting, refined data can then be forwarded to a central site for further treatment.

The demand on these mini data centres will be heavy. The large volume of data handled, in addition to creating its own heavy processing load, will probably make full data backup unaffordable. This will create a need for selective backup operations, in turn requiring even more processing.

These data centres must exhibit high availability, as they process real time data that would be lost if not captured on arrival. The IoT’s expected scale of operation makes efficiency essential as wasted energy at these levels translates into significant energy and cooling costs, and possibly green credibility damage. Flexibility and easy scalability is also important, allowing data centre capacity to cost-effectively track rapid growth in IoT device populations.

UPS Topologies

If high availability, efficiency and scalability are essential to the data centre ICT equipment, these attributes are equally critical to the uninterruptible power supply (UPS) supporting it. Today’s UPS systems are best able to meet such challenges if they are built using modern, modular topology.

Advances in semiconductor technology, especially IGBT devices, have led to the transformerless technology now found within most modern UPSs. The inverter output ac voltage level from these is sufficiently high to drive the load directly, without need for a step-up transformer.

Transformerless technology has become ubiquitous because it offers so many advantages. These include improved efficiency with a higher input power factor, lower input current harmonic distortion (THDi) and lower audible noise. Importantly, both capital andoperating costs are significantly reduced. Users seeking the ultimate in UPS availability, flexibility and cost-effectiveness can take advantage of hot-swappable, modular UPS topology; an advanced concept made possible through transformerless technology’s hugely reduced size and weight.

The hot-swappable, modular approach

Fig.1 below is an example of a hot-swappable, modular system. The UPS rack on the left has three modules, while that on the right has five. Each module is an entirely self-contained UPS of up to 100kVA capacity. Because it is hot-swappable, if it fails it can be removed simply and quickly, without having to take the UPS system off-line. It is just as easy to ‘plug in’ extra modules to gain extra capacity. Adding modules to a rack in this way is known as vertical scaling; this can be done without needing extra space, cabling or installation effort. If the rack is full, further capacity can be provided by populating additional racks – ‘horizontal scaling’. Large IoT device population growth could therefore be accommodated quickly and easily, and without interruption to power.

Fig.1: Rackmounted modular UPS configurations

This flexibility also allows redundant configurations to be set up easily and efficiently. A 120kVA load, for example, could be supported by either a pair of non-modular standalone 120kVA units – one of which is redundant – or by four 40kVA rack-mounting UPS modules, totalling 160kVA capacity. If one module fails, the remaining three have 120kVA capacity between them, which is enough to fully support the load. This is known as n+1 redundancy, where, in this case, n=3. During normal operation the redundant configuration’s capacity exceeds the load by only 40kVA, rather than 120kVA as in the standalone example. Capital expenditure on unnecessary extra capacity has been reduced, while each module’s loading has been increased to 75%, compared with 50% each for the 120kVA standalone pair.

As mentioned earlier, high availability is essential to avoid loss of data arriving in real time from arrays of IoT devices. Redundancy improves availability by providing resilience to failure, but modular systems with hot swapping capability can achieve availability levels up to 99.9999%, often known as ‘six nines availability’. Mean Time To Repair (MTTR) is a key determinant of availability – and this figure drops from around 6 hours for a standalone system to half an hour for a modular system. This is because modular system capacity can be immediately restored with a healthy module while the faulty unit is taken away for repair; by contrast, a non-modular system must remain off line while it is repaired internally.

Balancing performance and cost

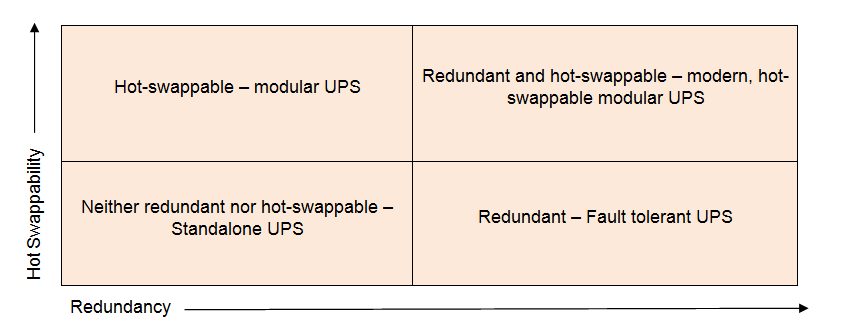

For UPSs supporting business critical loads such as an on-line banking network, a hot-swap, modular system as above is the best choice as it offers the highest possible power availability. However other UPS operators within less critical applications may wish to trade off some power availability against cost. The Power Availability (PA) chart shown in Fig. 2 below shows the trade-off choices that exist.

Fig.2: Power Availability (PA) chart, showing different UPS types

The PA chart categorises systems into quadrants according to how they offer high availability through redundancy and hot-swappability. Data centre managers can choose the solution that best balances their budget and level of need for high availability. For example, a standalone UPS, which is neither hot-swappable nor redundant, provides normal power availability based entirely on UPS reliability.

Power availability can be improved to some extent with a fault tolerant system that has redundant components, although many of these – including a high number of processor electronics and other critical items – are not hot-swappable. Such systems offer high power availability as they continue to support the load if a component fails. However a failed component can often mean that the entire UPS needs replacement; the repair will be expensive and time-consuming, causing system downtime and major inconvenience to the data centre manager.

Modular UPSs, like the fault-tolerant systems, offer high power availability. With multiple hot-swappable components, and often with redundant batteries, they are typically used for multiple servers and critical applications equipment. Their main advantage over a fault-tolerant UPS is that all main components susceptible to failure can be hot-swapped, eliminating planned downtime during a service call.

However, modern, modular UPS systems perform best on the PA chart due to all their major components, including power electronics, batteries and processor electronics being hot-swappable and redundant. As discussed above, these systems offer the highest levels of power availability and power protection for data centres and other IT operations currently available. They also make accommodation of future growth simpler, with easier handling of small, light units if the organisation moves or expands.

Meeting the IoT challenge

Growth in the IoT and its demand for real-time data processing is forecast to be dramatic, yet the IoT is also new and unpredictable, as is how technology and user’s needs will develop. With this in mind, UPSs must offer sufficient flexibility, through their scalability and availability credentials, to meet these potentially unknown challenges. At the same time, they must remain suitably space, cost and energy efficient to comply with data centre operators’ space and budget constraints. Modular UPS technology has already proved itself to be well suited to dealing with changing requirements and is well placed to play an important role in managing exponential growth in IoT data requirements, both now and in the future.