Welcome to the second article on preventative maintenance and the benefits it can bring to your critical power protection devices; uninterruptible power supplies, emergency lighting and battery solutions.

KOHLER Uninterruptible Power pride themselves on service excellence, making maintenance and response for your critical power system a priority. With a +90% first time fix rate and best-in-class customer NPS rating you can rest easy knowing you are in the best hands.

The components within KUP power protection devices are of a high quality to help ensure many years of trouble-free operation. In this second article we will discuss most common types of batteries, how to properly store them, routine maintenance and its benefits.

Battery types

Offering the best balance between cycles and costs, Valve Regulated Lead Acid (VRLA) batteries are now by far the most common choice for modern UPS systems and use lead and lead-oxide plates immersed in sulphuric acid electrolyte. This combination develops a nominal two-volt potential from each cell.

VRLA batteries are safer and much more environmentally friendly than earlier open-vented lead acid types or the lithium-ion types favoured for applications like energy storage which demand thousands rather than hundreds of cycles. This is because modern VRLA batteries are around 98% recyclable, with well-developed recycling infrastructure in most developed countries such as the reputable, trusted partners KOHLER Uninterruptible Power works with.

Unlike earlier open vented cells that needed regular topping up, today’s batteries are sealed units that require no user maintenance. A valve allows venting of gases generated in emergency/over-pressure situations, though the amount given off is so small that it can normally be handled by standard air handling equipment used to control temperature. On this point it is important to note that as a device based on temperature dependent chemical reactions, batteries require a temperature-controlled environment. The best balance between operating performance and lifetime is achieved at 20°C. As a rule of thumb, for every 10°C above this the working life will halve. The useful working life of the battery is also affected by how the battery is used, so great care must be taken when selecting and sizing batteries for a UPS installation.

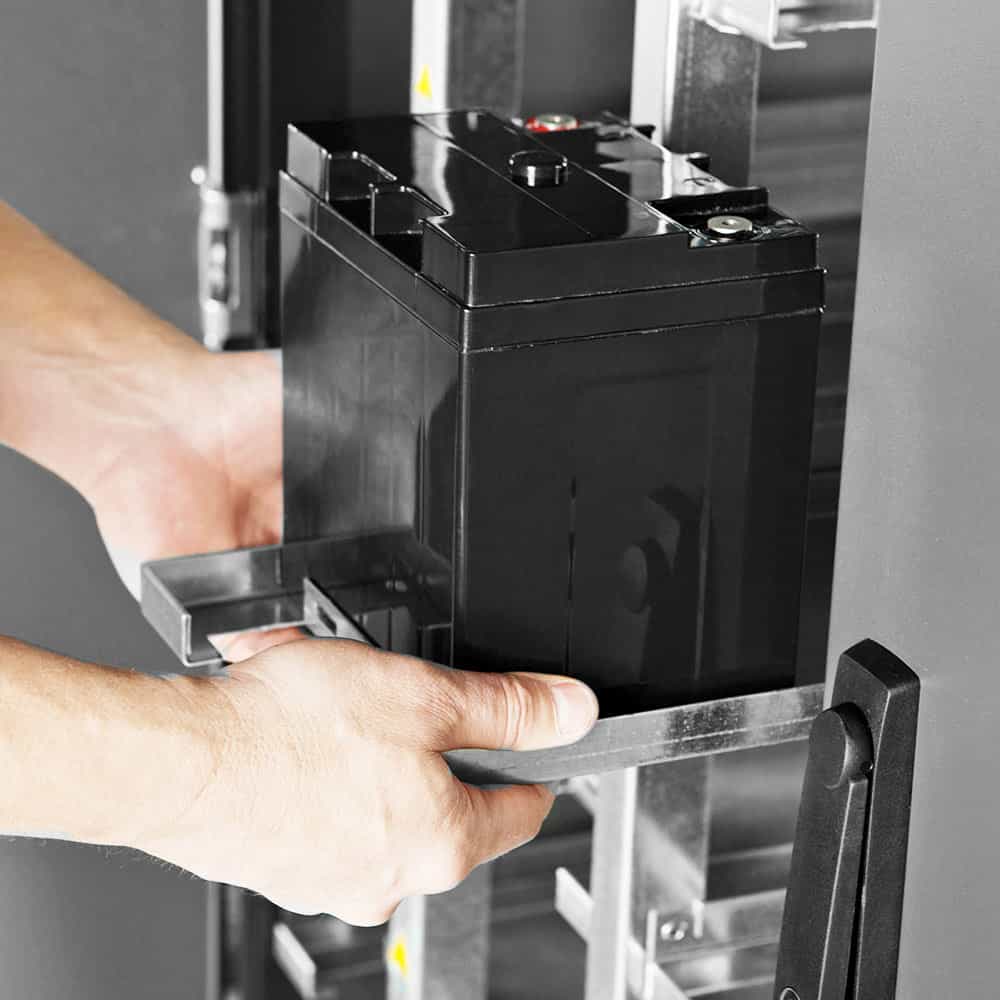

VRLA batteries can be housed in cabinets alongside the UPS rather than in separate battery rooms, even if the UPS are operating within an office environment. However, because the combined voltage of the battery system will be the same as a mains electricity supply, for safety reasons it should be protected from unauthorised or accidental contact.

How to store batteries?

Though robust in many ways, VRLA batteries are very temperature-dependent and must be kept within a temperature-controlled environment. Operation at significantly above the typically-recommended 20°C level will cause irreversible damage, whilst as mentioned earlier, life expectancy is approximately halved for each 10°C increase in average operating temperature. Low temperatures have negligible impact on service life but reduce performance ie the ability to deliver the voltage and autonomy for the critical load. Depending on the number of discharge cycles experienced and ambient temperature, a typical 10-year ‘design-life’ VRLA battery will last seven to eight years. Similarly a 5-year ‘design-life’ VRLA battery would be expected to last three to four years, hence why these tend not to be used in high quality systems.

Inspecting your batteries and what’s involved

A key benefit of routine battery maintenance is the early detection of weak battery blocks. As they are such a critical part of a power protection device, replacement of weak battery blocks should therefore take place before they fail. Due to batteries being arranged in sequential strings, if a replacement battery is not purchased, a weak or faulty battery will compromise the integrity of the whole power protection system.

Routine battery maintenance provided by our skilled team of specialist engineers includes:

- Checking the open circuit battery and UPS float voltages

- Taking block and string voltages

- Inspecting the physical condition of batteries, terminals and connections, including a detailed examination of individual cell for post and interconnector corrosion

- Environmental checks including ambient temperature and cleanliness eg levels of dust

- Assessing the condition of battery cabinets

Battery Management

Using web-based technology, modern battery management systems such as KUP’s PowerNSURE can check the internal resistance, temperature and voltage of every single battery sequentially. Through an equalisation process, the system then corrects the charging voltage operating range. This prevents gassing, dry-out and thermal runaway of batteries, ensuring availability. Battery monitoring also removes the need for manual battery impedance testing at each inspection, reducing maintenance contract cost.

Benefits of preventative maintenance when it comes to batteries

Battery issues are the most common source of physical UPS system failure. As outlined above modern UPS batteries ultimately depend upon temperature dependent chemistry and a failure in one block will often disable an entire battery string. Therefore whilst good quality batteries in a well designed system typically provide many years of reliable life, investment in a battery management system and preventative maintenance visits by a suitably trained and experienced engineer directly correlate to being able to:

- Ensure continuous uptime and availability of your UPS system

- Avoid the risk of additional costs for repair

- The ability to receive advance warning and allocate budget for future component replacement

If you have any questions about the health of your power protection system please get in touch with our Service Department: [email protected] or call 01256 386752